Rebar vs. Fiber Concrete: Choosing the Best Reinforcement for Your Project

People have used steel rebar to reinforce the tensile strength of concrete since the mid-1800s, and with good reason. While concrete is a versatile, cost-effective building material, it needs more tensile strength to boost its durability. Engineering has advanced greatly since the 19th century, and the advent of fiber mesh and reinforcement has revolutionized concrete’s potential as a structural foundation and a way to beautify a space. In this guide, you’ll learn the difference between rebar and fiber reinforcement and discover the best option for your project.

Why Do Concrete Structures Need Reinforcement?

While concrete does very well with compressive or “pushing” forces, it’s less adept at enduring tension or “pulling” forces, handling only 10% to 15% of the force it could withstand under compression. This lack of tensile strength leads to cracks and even breaks in concrete slabs, foundations, walls, pavements and columns that threaten the structure’s integrity. When concrete is paired with a material like steel rebar, wire mesh or fiber, the reinforcement carries some of the tensile load and helps hold the concrete together.

What Is Rebar Reinforced Concrete?

Rebar reinforcement is a series of thick, often ridged steel rods inserted into concrete to form a composite material that performs better under tension. The bars are usually arranged in a grid pattern to distribute the force equally across the structure and are laid down before the concrete is poured. Steel is an excellent material for rebar because it expands and contacts at a similar rate to concrete when temperatures fluctuate. It also has great tensile strength.

Advantages of Rebar Concrete Reinforcement

Steel rebar is used in many construction projects, including commercial, industrial and residential buildings, infrastructure like roads and bridges and large structures like dams, tunnels and processing plants. The benefits of using rebar to reinforce your concrete structure include:

- It vastly increases the load capacity of concrete by enhancing its tensile strength with steel.

- You control where the reinforcing material is placed within the concrete to optimize reinforcement distribution.

- Rebar concrete produces warning-sign cracks so the structure doesn’t suddenly break when under too much tension.

- Per unit weight, steel rebars are generally a more cost-effective solution to concrete reinforcement.

Drawbacks of Rebar Concrete Reinforcement

Although rebar significantly supports concrete structures, it poses a handful of challenges to both construction companies and building owners. Some of the cons of using rebar as a reinforcing agent are:

- Steel rebar is vulnerable to corrosion if exposed to salty sea water or ice-preventing road salt.

- When cracks appear, they are generally deeper and expose the concrete to more corroding chemicals.

- Once corrosion sets in, the structural integrity of the concrete begins to decline rapidly.

- Rebar requires careful planning, heavy-duty transportation and significant labor to install.

Is Rebar the Same as Wire Mesh?

Wire mesh is similar to rebar in using crosshatched steel to reinforce concrete. However, while rebar is usually thick and laid out in a grid pattern onsite, wire mesh is thinner, comes pre-welded or woven and is laid on top of the wet concrete. Because wire mesh is not as robust as rebar, it’s often used as lighter reinforcement in places with limited space.

What Is Fiber Reinforced Concrete?

While fiber reinforcement also somewhat increases the tensile strength of concrete, its primary purpose is to boost a structure’s toughness and crack resistance. Fiber concrete is made using small fragments of material mixed into the concrete and not laid down before pouring. These fibers can be made of numerous materials, including steel slivers, plastic, glass, basalt and cellulose. They also come in two size variations — macro- and microfibers — which help reinforce the concrete at different drying stages:

- Microfibers: Microfibers are made of flexible, synthetic materials and are usually smaller than half an inch in length. They help prevent cracks from forming in freshly laid concrete one to six hours after pouring. These initial cracks, known as plastic shrinkage cracks, happen when hot weather or high winds cause wet concrete to lose water too quickly.

- Macrofibers: Macrofibers help keep hardened concrete tough for years to come. They are usually made of more rigid material like steel or glass and are larger than half an inch long. When cracks start forming from too much tension on the concrete, macrofibers keep these cracks small by holding the two sides together.

Advantages of Fiber Concrete Reinforcement

Fiber reinforcement stabilizes thinner layers of concrete, such as pathways, artistic building facades, decorative elements and ground-level concrete driveways, where rebar would not fit. Fiber is also used alongside rebar to give concrete structures the best combination of tensile strength and toughness. Some advantages of fiber concrete reinforcement are:

- Fibers keep cracks small and stable, preserving the sleek appearance of concrete.

- Smaller cracks lead to less corrosive chemicals pooling in cracks and compromising the steel within.

- Reinforcing fibers are easier to transport and apply during construction.

- They can be used to boost toughness in delicate concrete fixtures that would otherwise be left unreinforced.

Drawbacks of Fiber Concrete Reinforcement

Using fiber to boost toughness does come with a handful of challenges. Consider these points if you plan to use fiber alone to reinforce your concrete structure:

- Fibers are mixed into the concrete slurry, so they are randomly distributed. This means some concrete slab areas may not be optimally reinforced.

- Fiber is less cost-effective than traditional steel rebar per unit weight.

- The finishing process can be more labor-intensive as fibers sometimes poke out of the surface of the concrete.

Is Fiber Mesh Concrete the Same as Fiber Reinforcement?

Fiber mesh concrete reinforcement comes in prefabricated nets that are laid flat onto the wet concrete like wire mesh. Because fiber mesh is one uniform sheet, it doesn’t distribute toughness as thoroughly throughout concrete as individual fibers. It does make for easier finishing and more uniform horizontal support.

How Do Rebar and Fiber Concrete Compare?

Fiber and rebar excel at different jobs and are thus better suited to different projects. This summary weighs up the two options for easy comparison:

| REBAR VERSUS FIBER CONCRETE REINFORCEMENT | ||

|---|---|---|

| FEATURES | REBAR | FIBER |

| Durability and Strength | Adds immense tensile strength to concrete structures | Adds some tensile strength to concrete structures |

| Crack Prevention | Prevents a crack from becoming an instant break in dry concrete | Prevents plastic shrinkage cracks and holds cracks in dry concrete together, keeping them small |

| Versatility | Is best used in large, heavy-duty structures like foundations, bridges and buildings | Adds toughness to any concrete structure and reinforces thinner concrete layers like sidewalks and driveways |

| Risk of Corrosion | Steel rebars can rust if exposed to salt or excess moisture through cracks | Synthetic fibers don’t corrode and minimize corrosion damage to underlying rebar |

| Ease of Application | Requires more effort to transport and lay down into a grid | Requires less effort as it’s mixed directly into slurry |

| Cost-Effectiveness | More cost-effective per unit weight with higher labor costs | Less cost-effective per unit weight with lower labor costs |

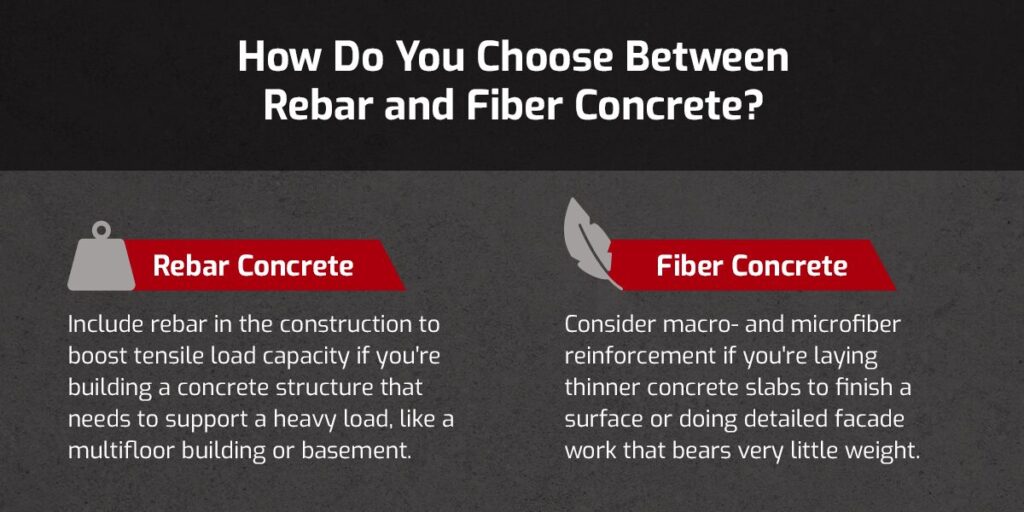

How Do You Choose Between Rebar and Fiber Concrete?

If you’re laying thinner concrete slabs to finish a surface or doing detailed facade work that bears very little weight, consider macro- and microfiber reinforcement for more freedom and less effort. If you’re building a concrete structure that needs to support a heavy load, like a multifloor building or basement, it’s highly recommended to include rebar in the construction to boost tensile load capacity.

Ultimately, combining rebar and fiber reinforcement gives your concrete driveway, pillar, ceiling or load-bearing wall the best of both worlds. You get the highest tensile strength boost with your rebar grid, while the fibers prolong the life of that rebar by keeping cracks thin and preventing steel corrosion.

Optimize Your Project With R. J. Potteiger Construction Services, Inc.

At R. J. Potteiger Construction Services, Inc., we’re dedicated to innovation, efficiency, exemplary service and brilliant results. From concrete driveways to large-scale building projects, our capable staff, state-of-the-art tools and decades of experience make us right for the job. If you’re located in central Pennsylvania and need a concrete project completed by licensed professionals in a timely and skilled manner, request a quote online today.